Wafer connector interface specifications

2025-01-20 10:13:18

2025-01-20 10:13:18

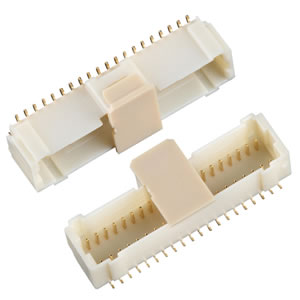

The wafer connector interface specification covers various aspects such as electrical, mechanical, and environmental adaptability to ensure its efficient, stable, and safe operation in different application scenarios. Firstly, the connector's interface layout design can adopt single-row or double-row pin configurations, with the specific choice depending on the space and the number of connection points required. Common pin numbers range from 2 to multiple pins, and the arrangement is typically in a straight or staggered pattern to ensure good contact and stable insertion and removal. Regarding electrical performance, the connector's rated voltage and current are generally 250V and from 0.5A to 10A, with contact resistance required to be controlled below 10 milliohms. The dielectric strength should reach 1500V AC to ensure electrical isolation and stable signal transmission. The insulation resistance is generally required to be over 1000MΩ to prevent short circuits and leakage.

Regarding mechanical performance, the insertion and removal force should be controlled between 5N and 30N to ensure smooth operation without loosening. The connector's insertion and removal life should last at least 1000 cycles to meet long-term usage requirements. To adapt to harsh environments, the connector should also have vibration and shock resistance, complying with relevant standards such as IEC 68-2-6 and IEC 68-2-27. In terms of environmental adaptability, the connector should operate within a temperature range of -40°C to +105°C, with a typical waterproof and dustproof rating of IP40. Specific applications may require higher protection levels, such as IP65. Additionally, the connector's materials should have good ultraviolet (UV) resistance and chemical corrosion resistance, especially when used in outdoor or industrial environments.

Regarding material selection, the conductive parts of the connector are commonly made of gold-plated or silver-plated copper alloys to ensure low contact resistance and high conductivity. The insulating parts are typically made of high-performance plastics with excellent heat resistance and electrical insulation properties, such as PBT, PA, and LCP. Surface treatments like gold plating enhance conductivity and oxidation resistance. Finally, the connector should comply with international standards such as IEC, UL, RoHS, etc., ensuring compatibility and safety on a global scale. Through these comprehensive designs, wafer connectors can provide stable and reliable electrical connections in various industrial, communication, and automotive fields, meeting the requirements of different application environments.