Difference Between Wafer Connectors and FIT Connectors

2025-01-09 09:50:14

2025-01-09 09:50:14

Design and Structure:

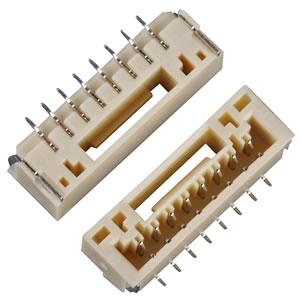

Wafer Connectors: Wafer connectors are typically designed with a flat, rectangular shape and are used for board-to-board or board-to-cable connections. They often feature multiple contact points arranged in a row and are known for their compact design, making them suitable for applications where space is limited.

FIT Connectors (Flexible Interconnect Technology): FIT connectors, on the other hand, are designed to provide flexibility in interconnect applications. They are often used for connecting flexible printed circuits (FPC) or flat flexible cables (FFC) to printed circuit boards (PCBs). FIT connectors are known for their ability to accommodate flexible connections and are often used in applications requiring durability and a high degree of flexibility.

Application:

Wafer Connectors: These connectors are commonly used in consumer electronics, automotive systems, and industrial equipment where reliable, compact connections are needed.

FIT Connectors: FIT connectors are typically used in more specialized applications, such as medical devices, mobile devices, and other electronics that require flexible connections with high reliability.

Connection Method:

Wafer Connectors: Usually involve a straightforward plug-and-socket type connection. They are designed for easy insertion and removal, making them suitable for applications where components may need to be replaced or reconnected frequently.

FIT Connectors: Often involve more specialized connection methods, such as zero insertion force (ZIF) or low insertion force (LIF) mechanisms. These methods are designed to minimize wear and tear on the connectors and to provide a secure, reliable connection even in demanding environments.

Cost and Availability:

Wafer Connectors: Generally more cost-effective and widely available due to their simple design and widespread use in various industries.

FIT Connectors: Typically more expensive due to their specialized design and the materials used to accommodate flexible connections. They may also be less widely available, depending on the specific requirements of the application.

In summary, wafer connectors are ideal for compact, standard connections in a wide range of applications, while FIT connectors are better suited for specialized applications that require flexible, durable connections with specific performance characteristics.