Understand the working principle and advantages of FPC connector.

2024-01-25 13:41:39

2024-01-25 13:41:39

FPC connector is a small technology used in electronic equipment. It connects different electronic components and makes them communicate with each other. This connector is specially designed for connecting flexible printed circuits. (Flexible Printed Circuits, FPC for short), and Flexible Flat Cables (FFC may also be connected).

The working principle of FPC connector is quite direct, but it is also very interesting. Flexible plastic strips are designed to transmit electrical signals between different parts of equipment because they are printed with thin metal wires. Each metal wire is an independent path of electrical signals, and each signal can carry different types of information. When FPC connector is connected with equipment, it builds a bridge between different parts and forms a stable electrical connection. Then, when the equipment is turned on, electrical signals will flow along these wires, so that different parts of the equipment can communicate with each other.

There are two key steps in using FPC connector: first, find the open end of FPC connector, and gently slide the flexible cable into this slot to ensure that it is completely inserted; Then, close the small lock to ensure that the cable will not loosen.

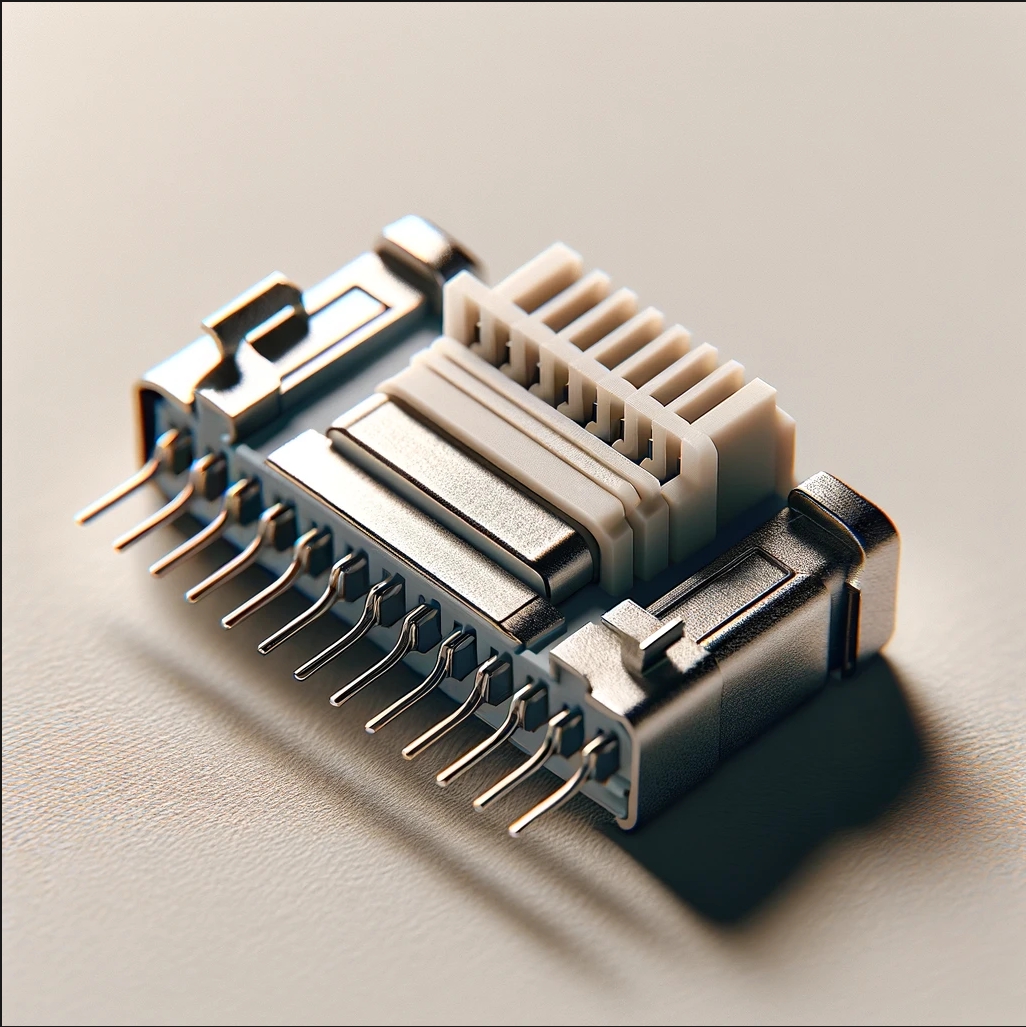

There are several different types of FPC connectors, including right-angle connectors, linear connectors and surface mount connectors. The right-angle FPC connector is very useful when the space is tight or the design requires the cable to turn 90 degrees. Surface mount FPC connector is used in the case that the connector needs to be directly attached to the surface of the equipment circuit board, which occupies a small space and is very suitable for smaller electronic equipment.

FPC connector is different from FFC connector, which is specially designed for planar flexible cable interface. These cables are made of two layers of polyester insulation and thin rectangular copper conductors. FFC connector is favored because of its high density, easy assembly and flexibility, especially suitable for equipment with tight space. FPC connector is designed for flexible printed circuit interface, which is light and flexible and can adapt to different shapes and sizes.

Knowing the types, usage and maintenance of FPC connectors can help you use them effectively. Correct knowledge and handling enable FPC connectors to significantly improve your electronic projects.