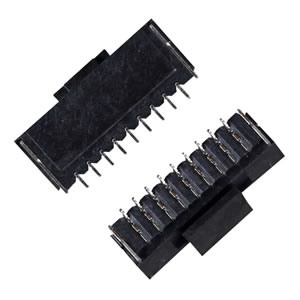

How to Choose the Right WAFER Connector

2025-04-19 10:41:29

2025-04-19 10:41:29

When selecting a WAFER connector, it is essential to comprehensively consider multiple factors such as the application scenario, electrical performance, structural form, material process, and environmental conditions. Whether it is a board-to-board or wire-to-board connection, it is crucial to first clarify the voltage, current, signal type, and insertion/extraction frequency the connector needs to handle. Then, appropriately choose the pin pitch (e.g., 1.0mm, 1.25mm, 2.0mm, etc.), number of pins, mounting method (SMT or DIP), mating direction, and whether a locking mechanism is required. At the same time, attention should be paid to the material properties of the connector, ensuring that the plastic components meet flame-retardant standards, the terminal contact resistance is low, the insertion lifespan is long, and the connector complies with RoHS and other environmental regulations. For different application industries, such as industrial equipment, automotive electronics, or consumer products, structural compatibility factors like vibration resistance, temperature tolerance, and spatial layout must also be considered. To ensure accurate and reliable selection, it is recommended to follow a process of "initial screening – sample testing – small batch trial – mass production verification," combined with structural and electrical testing and supplier evaluation to comprehensively reduce design risks. A high-quality, well-suited connector not only ensures the overall performance stability of the device but also affects assembly efficiency, delivery cycle, and user experience. Therefore, a scientific and systematic selection approach has become an essential core competency for every hardware engineer.