Differences Between Wafer Connectors and WTB (Wire-to-Board) Connectors

2025-02-24 11:11:57

2025-02-24 11:11:57

The main differences between Wafer connectors and WTB (Wire-to-Board) connectors are as follows:

1. Definition and Application

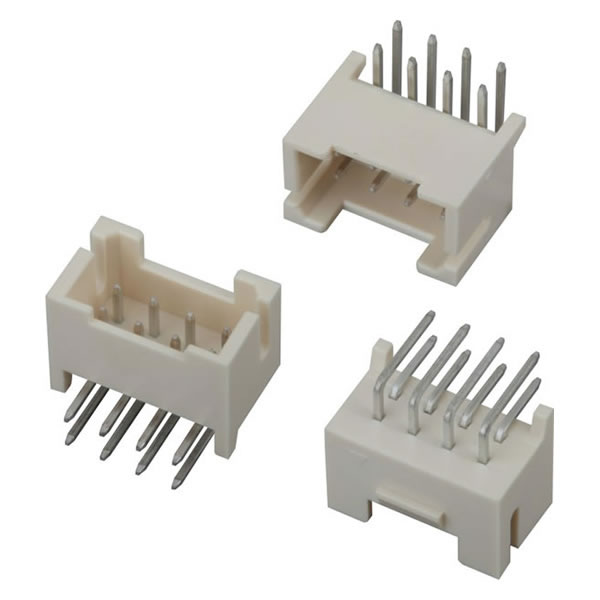

· Wafer Connector: Generally refers to a Board-to-Board (B2B) or Wire-to-Board (WTB) connector with a plastic housing. Its terminals are usually embedded in the plastic shell and are primarily used for connections between PCB boards or between a PCB board and a cable.

· WTB (Wire-to-Board) Connector: Specifically refers to wire-to-board connectors, which connect wires to a PCB board via terminals. They are suitable for electronic devices that require external cable connections, such as power supplies and signal transmission.

2. Structural Differences

Comparison Item | Wafer Connector | WTB Connector |

Connection Type | Board-to-Board (B2B) or Wire-to-Board (WTB) | Wire-to-Board |

Terminal Type | Pins or sockets, commonly single-row or double-row | Mainly wire terminals and PCB sockets |

Terminal Installation | Fixed by SMT or THT soldering | Wire-end crimping, board-end soldering or plug-in |

Common Pitch Sizes | 0.8mm, 1.0mm, 1.27mm, 2.0mm, 2.54mm, etc. | 1.25mm, 2.0mm, 2.54mm, 3.96mm, etc. |

Application Scenarios | PCB-to-PCB connection, signal transmission | Power cables, data cables to PCB connections |

3. Application Scenarios

· Wafer Connector: Widely used in consumer electronics (such as laptops, televisions, mobile phones), automotive electronics, industrial equipment, etc.

· WTB Connector: Suitable for household appliances, power supplies, industrial equipment, and other applications requiring cable connections.

4. Selection Recommendations

· If a PCB needs to be directly connected to another PCB or soldered onto a PCB for plug-in use, a Wafer connector is recommended.

· If a wire harness needs to be connected to a PCB, a WTB connector is recommended, as it is better suited for flexible wiring applications.