The Working Principles and Design Features of FPC Connectors.

2023-12-29 09:21:37

2023-12-29 09:21:37

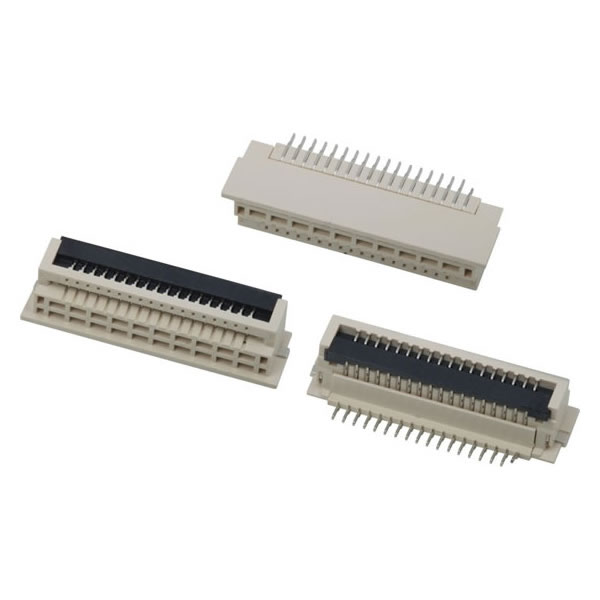

FPC connectors, also known as flexible printed circuit connectors, are electronic components used to connect flexible printed circuit boards. FPC connectors themselves are made of flexible materials printed with conductive copper lines, such as polyimide or polyester, used to manufacture lightweight and bendable electronic circuits. The design and principle of FPC connectors aim to meet the special needs of these flexible circuits, providing them with a stable and reliable electrical connection.

The working principle of FPC connectors is to connect the conductive paths on the FPC through physical contact points. Typically, these contact points are made of metal (such as copper, nickel, or gold) to ensure good conductivity. To achieve an effective connection, when the end of the FPC is inserted into the connector slot, the contact points need to make close contact with the corresponding circuits on the FPC, thus establishing an electrical connection. In this process, the contact points must apply moderate pressure to maintain the connection but not excessive pressure to avoid damaging the fragile structure of the FPC.

To ensure the stability and durability of the connection, many FPC connectors are equipped with locking mechanisms. These mechanisms can be simple snap designs or more complex flip or slide locks. The purpose of the locking mechanism is to maintain the position of the FPC within the connector, preventing connection failures caused by vibration or tension.

In terms of electrical characteristics, the design of FPC connectors needs to ensure low contact resistance and good signal integrity. Low contact resistance can effectively transmit current, avoiding excessive heat and energy loss. High signal integrity is essential for reliable data transmission, especially in high-frequency applications.

In terms of material selection, flexible printed circuit board (FPC) connectors typically use materials with corrosion resistance and high conductivity for contact points and high-temperature-resistant plastics for the housing to withstand the high temperatures of the soldering process and thermal stress in daily use.

Overall, the working principle of FPC connectors is to construct a mechanical structure that can adapt to the flexibility of FPC while providing a stable and reliable electrical connection. Through precise design and material selection, the performance of the connection is ensured, meeting the demands of modern electronic devices for miniaturization and high reliability.